Laser-assisted advanced manufacturing of metal structures

Understanding how laser light interacts with a modifies materials will help guide the next generation of laser source development in NIF&PS. In collaboration with Engineering and WCI, a team of scientists and engineers in NIF&PS are working towards optimizing approaches for advanced laser materials processing such as laser powder bed fusion additive manufacturing and controlled laser ablation of metals.

As part of this work, researchers design and perform detailed experiments to study the physics of laser-material interaction at various time and length scales. Precise and tailored laser heating of metal surfaces will be used to drive microstructural evolution, surface modification and material removal for a wide range of mission applications.

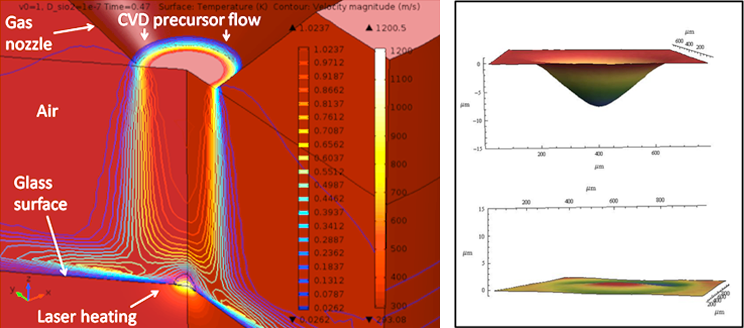

IR laser microshaping of silica optics: rapid ablation mitigation

We collaborated with development teams in NIF to successfully develop laser-based techniques to repair optical damage on fused silica optics used in the NIF laser. LLNL expertise in CO2 laser processing of glass optics dates back to the early '80s, and more recently, detailed models of the laser-material interaction and response has led to a better understanding of the physics involved.

To overcome structural relaxation and Marangoni flow problems associated with long laser exposures, the group shifted laser parameters towards shorter pulse, small beam diameter to effectively 'machine' away material, leaving a precise micro-shaped mitigation site. The process, Rapid Ablation Mitigation, or RAM, is currently used in the NIF for damage repair.

Laser-based chemical vapor deposition

We have developed methods to replenish material lost to optical damage thereby refurbishing the optical component, using laser-based chemical vapor deposition (L-CVD). While damage repair using laser ablation (e.g. RAM) has been successful, the removal of glass necessarily modulates the light passing through the optic, albeit at very low levels. Ideally, material lost to the original damage event is replenished thereby preventing loss of light and introduction of light modulation. Because of the non-equilibrium conditions driving by rapid laser heating, L-CVD is also being explored as a means to produce ultra-hard materials for defense applications and NIF target capsules.

- Ibo Matthews

- Jenny Wang

- Selim Elhadj

- Jae Yoo

- Nan Shen

- Gabe Guss

- Isaac Bass

- Phil Depond

- Nick Calta

- Tien Roehling

M. J. Matthews, G. Guss, S. A. Khairallah, A. M. Rubenchik, P. J. Depond, and W. E. King, "Denudation of metal powder layers in laser powder bed fusion processes," Acta Materialia 114, p. 33, 2016.

C. A. R. Chapman, L. Wang, J. Biener, E. Seker, M. M. Biener, and M. J. Matthews, "Engineering on-chip nanoporous gold material libraries via precision photothermal treatment," Nanoscale 8, p. 785 2016. (Cover Article)

M. J. Matthews, S. T. Yang, N. Shen, S. Elhadj, R. N. Raman, G. Guss, et al., "Micro-Shaping, Polishing, and Damage Repair of Fused Silica Surfaces Using Focused Infrared Laser Beams," Advanced Engineering Materials, vol. 17, p. 247, 2015. (Cover Article)

J.-H. Yoo, J. B. In, I. Sakellari, R. Raman, M. Matthews, S. Elhadj, C. Zheng, and C. Grigoropoulos, "Directed dewetting of amorphous silicon film by a donut-shaped laser pulse," Nanotechnology 26, 165303 (2015).

S. Elhadj, M. J. Matthews, and S. T. Yang, "Combined Infrared Thermal Imaging and Laser Heating for the Study of Materials Thermophysical and Processing Properties at High Temperatures," Critical Reviews in Solid State and Materials Sciences 39, 175-196 (2014).

S. Ly, A. M. Rubenchik, S. A. Khairallah, G. Guss, and M. J. Matthews, "Metal vapor micro-jet controls material redistribution in laser powder bed fusion additive manufacturing," Nature Sci Reports 7, p. 4085, 2017.