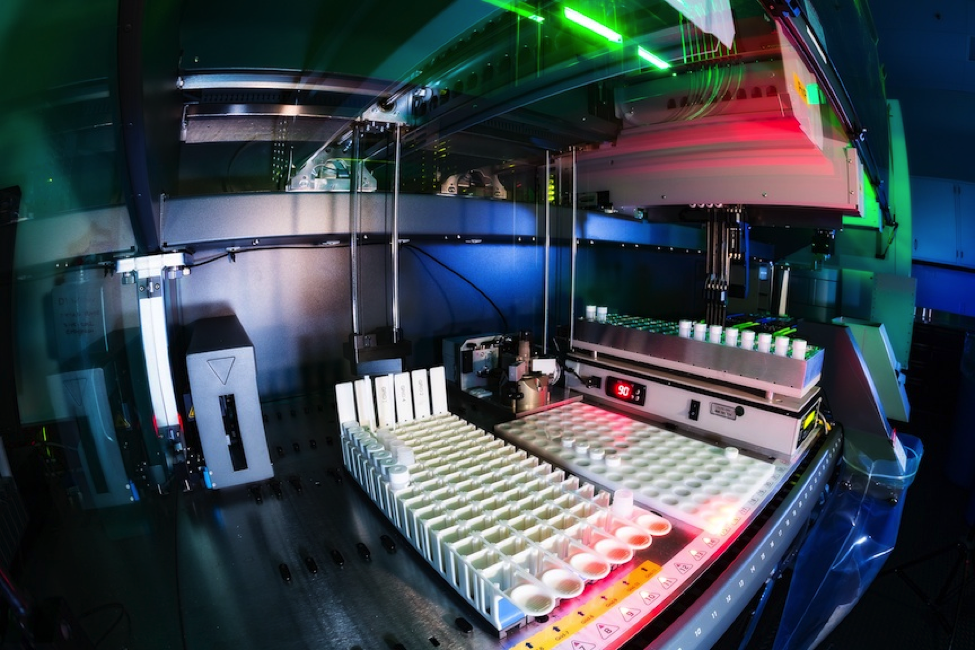

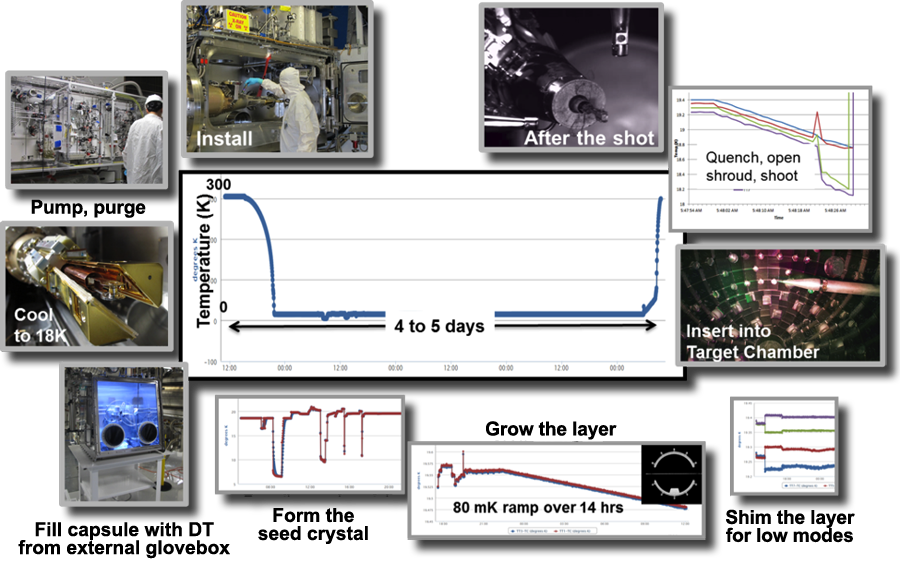

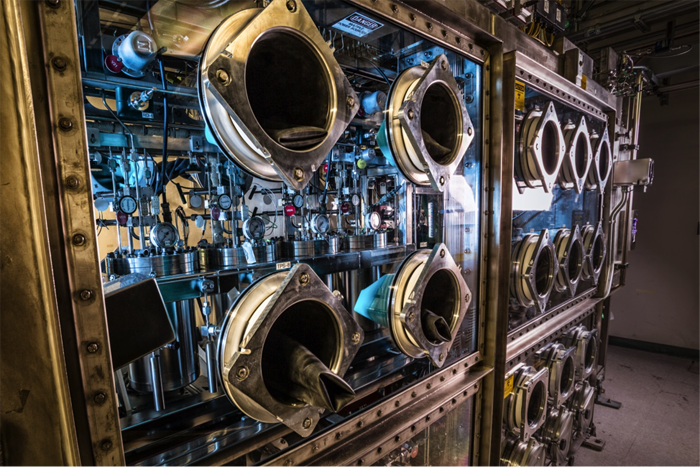

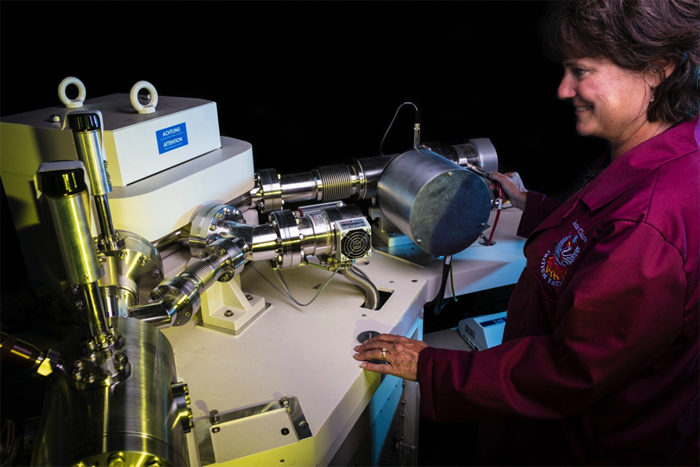

We work with our peers in the National Ignition Facility (NIF) and Engineering directorates to develop equipment, processes, and procedures needed to field experiments on NIF. New target materials and target diagnostics are assessed for their impact on operational cleanliness. We play a critical role in designing, commissioning, and enhancing capabilities for target gas fill and cryogenic target positioning/layering systems and as well as provide expertise to enable fielding new experiments on NIF. A novel rapid assessment capability for beryllium dispersion has enabled incorporation of beryllium targets and diagnostics into routine NIF operations while maintaining personnel safety and high shot rate.