We use additive manufacturing methods to create novel optics that contain gradients in material properties with an eye toward broadening the tradespace available to optical system designers. Current components of interest include silica glass with gradient in refractive index, low-thermal-expansion glass supports, yttrium aluminum garnet with gradient in dopant profile, and high-stiffness, ultra-lightweight mirrors.

The effort has resulted in the creation of first-of-their kind optics prepared using layer-by-layer additive manufacturing methods.

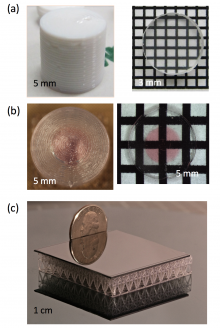

(a) A specially formulated garnet-containing paste or “ink” is extruded to form a low density cylindrical structure (left) using a direct ink write (DIW) printer. Ceramics processing techniques are then used to transform it into a fully dense, transparent ceramic monolith (right).

(b) A patterned, low density silica structure (left) is printed using two new silica-containing DIW inks, one doped with gold nanoparticles that give it a pink color. The low density part is then heat treated to form a fully dense, transparent glass (right) exhibiting regions of differing composition.

(c) A 50-mm mirror, consisting of a reflective surface and a support structure, is made lightweight using a graded-density lattice built by a layer-by-layer, selective photo-polymerization technique.

- Paul Ehrmann

- Lana Wong

- Koroush Sasan

- Lemuel Perez-Perez

- Nerine Cherepy

- Eric Duoss

- Rebecca Dylla-Spears

- Tyler Fears

- Bryan Moran

- Nikola Dudukovic

- Du Nguyen

- Steve Payne

- Zach Seeley

- Tim Yee

I.K. Jones, Z.M. Seeley, N.J. Cherepy, E.B. Duoss, S.A. Payne, Direct ink write fabrication of transparent ceramic gain media, Optical Materials, 75 (2018) 19-25.

D.T. Nguyen, C. Meyers, T.D. Yee, N.A. Dudukovic, J.F. Destino, C. Zhu, E.B. Duoss, T.F. Baumann, T. Suratwala, J. Smay, R. Dylla-Spears, “3D Printed Transparent Glass,” Adv. Mater. 2017, 29, 1770185