Understanding and controlling laser material interactions is an LLNL core competency with central importance to high-energy-density (HED) science and NNSA missions. This includes optical material reliability in the advanced laser systems we build, laser effects in directed energy weaponry, and the fundamental processes behind laser-based material processing. Material conditions span regimes from laser-melting up to the onset of warm dense matter formation. The laser-material physics behind all three missions is strongly linked, leveraging similar tools and expertise.

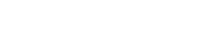

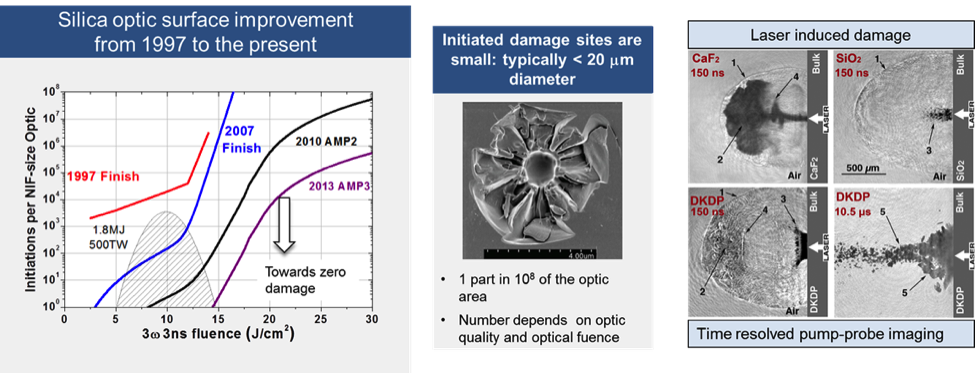

Laser systems for scientific and national security missions operate under extreme light levels that can result in degradation and damage to key optical components. This is particularly true of the National Ignition Facility (NIF), which operates at fluences beyond the UV damage threshold of its final optics. Similarly, many of our other current and planned programs—High-Repetition-Rate Advanced Petawatt Laser System (HAPLS) for the European Union’s Extreme Light Infrastructure, Compton sources, laser-based particle accelerators, and inertial fusion energy— subject optics to high pulse fluence and average power; optics for the diode-pumped alkali laser (DPAL) see very high average continuous-wave power under harsh chemical conditions.

Understanding the laser–material interactions responsible for optical damage is essential to design and operation of all of these lasers and to development of approaches to reduce and mitigate damage. Our research scientists have made significant progress understanding the processes which result in damage, the underlying causes of damage, and the development of processes to reduce and control damage from the femtosecond to the nanosecond regime.

- Jeff Bude

- Manyalibo Matthews

- Ted Laurence

- Raluca Negres

- Phil Miller

- Nan Shen

- Sonny Ly

- Selim Elhadj

- Rusty Steele

- Lana Wong

- Salmaan Baxamusa

- Pam Whitman

- Rajesh Raman

- Roger Qiu

- Tayyab Suratwala

J. Bude, P. Miller, S. Baxamusa, N. Shen, T. Laurence, W. Steele, T. Suratwala, L. Wong, W. Carr, D. Cross and M. Monticelli, "High fluence laser damage precursors and their mitigation in fused silica," Opt. Exp. Vol. 22, 5839 (2014), LLNL-JRNL-648575.

P. E. Miller, J. D. Bude, T. I. Suratwala, N. Shen, T. A. Laurence, W. A. Steele, J. Menapace, M. D. Feit, and L. L. Wong, "Fracture-induced subbandgap absorption as a precursor to optical damage on fused silica surfaces," Optics Letters 35, 2702-2704 (2010).

S.G. Demos, R.N. Raman, R.A. Negres, "Time-resolved imaging of processes associated with exit-surface damage growth in fused silica following exposure to nanosecond laser pulses," Opt. Exp., Vol. 21, 4875, Feb. 2013.

C. W. Carr, J. D. Bude, and P. DeMange, "Laser-supported solid-state absorption fronts in silica," Physical Review B 82, 184304 (2010).

R. Negres, M. Norton, D. Cross, C.W. Carr, "Growth behavior of laser-induced damage on fused silica optics under UV, ns laser irradiation," Opt. Exp. vol. 18, 19966, 2010.

T. I. Suratwala, P. E. Miller, J. D. Bude, W. A. Steele, N. Shen, M. V. Monticelli, M. D. Feit, T. A. Laurence, M. A. Norton, C. W. Carr, and L. L. Wong, "HF-Based Etching Processes for Improving Laser Damage Resistance of Fused Silica Optical Surfaces," Journal of the American Ceramic Society 94, 416-428 (2011).