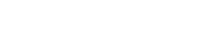

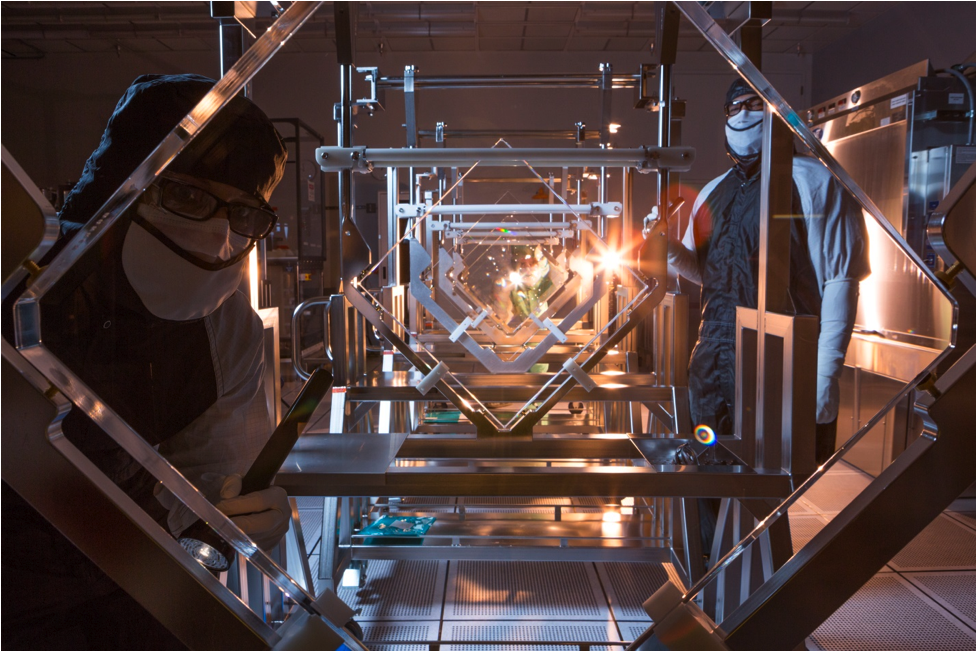

All National Ignition Facilty (NIF) optics (>14,000 to date) are cleaned and coated in the Optics Processing Facility, a Class 100 cleanroom. Research activities to support the OPF are directed at reducing surface damage of optics (primarily fused silica) once they are installed on NIF. Optic cleanliness (removal of molecular contaminants and particles) is key to maximizing the 3ω damage resistance.

Three processes are used to apply sol-gel anti-reflective coatings to optics in the OPF: dipcoating, meniscus coating, and spin coating. Research activities into anti-reflective coatings aim to increase the uniformity and stability of coatings. There is also on-going research into protective optical coatings, designed to reduce surface damage to optics.

Optics processing videos

- Take a ride along NIF's optics recycle loop

- Laser Damage Resistant Anti-Reflection Grating Debris Shield (AR-GDS)

Optics processing images

- Marcus Monticelli

- Diana VanBlarcom

- Pam Whitman

- Paul Ehrmann

- Phil Miller

- Selim Elhadj

- Sal Baxamusa

- Tayyab Suratwala

- Rusty Steele

S. Elhadj, W. A. Steele, D. S. VanBlarcom, R. A. Hawley, K. I. Schaffers, and P. Geraghty, "Scalable process for mitigation of laser-damaged potassium dihydrogen phosphate crystal optic surfaces with removal of damaged antireflective coating," Appl. Opt. 56, 2217-2225 (2017).

T. Suratwala, P. Miller, J. Bude, W. Steele, N. Shen, M. Monticelli, M. Feit, T. Laurence, M. Norton, C. Carr, L. Wong, “HF-based etching processes for improving laser damage resistance of fused silica optical surfaces” Journal American Ceramic Society 94 (2) (2011) 416-428.

J. J. DeYoreo, A. K. Burnham, and P. K. Whitman, “Developing KH2PO4 and KD2PO4 crystals for the world’s most power laser,” International Materials Review 47 (2002) p. 113-152.

J. A. Britten, "A simple theory for the entrained film thickness during meniscus coating," Chemical Engineering Communications 120 (1993) p. 59-71.